/ WHAT WE DO

Spray and skimmer finishing

Ideal on whole hides, splits, buffed and full florals, spray finishing is central to the production of many items, from furniture, bodywork, leather goods, shoes, oiled, waxed and vintage items.

How does the spray finishing work?

An advanced machine for perfect results: spray finishing. This type of three-cabin finishing, is carried out by employing machinery consisting of large drying tunnels alternating with spraying cabins, in which the hides are run. Inside each of the three booths, there are different guns that, thanks to specific movements at high speed and controlled pressure, spray on the surface of the leather, to change its color and effect.

Foamy Finish for Defective Skins

What if the leather has many defects? In this case, we opt for spray finishing with a foaming machine, a machine ideal for producing very fine and homogeneous foams. This treatment makes it possible to improve print memory on the finished leather and cover the deepest defects thanks to the formation of micro air pockets in the chemical compound sprayed onto the leather. To ensure high standards of color repeatability, the color laboratory identifies the ideal blend of pigments and compound using two dispensers: a laboratory one for sampling and an industrial one for production. Tirrena also flanks physical tests carried out by outsiders (rubbing, abrasion, bending, adhesion tests, etc.) to always ensure the high quality of the leather.

Do you want more information?

CONTACT US! FILL OUT THE FORM WITH YOUR REQUEST.

Why choose Tirrena Pelli?

Choosing Tirrena Pelli means combining handcrafted excellence and respect for the environment. Each leather is treated with eco-friendly techniques that minimize environmental impact, offering an authentic and sustainable product. Thanks to the’meeting of technological innovation and craftsmanship, each project becomes an exclusive experience.

Certified and traceable production process

The basis of Tirrena's work is ethics and transparency, LGW Gold level certified, a guarantee of a controlled and responsible supply chain. Each stage of the production process is traceable, allowing customers to verify firsthand the’commitment to sustainability.

The phases of finishing by spraying and with foaming machine

01

Delivery and collection for companies

Customer care starts with logistics: Tirrena Pelli offers a complete delivery and pickup service, including transportation, to best support companies that need a reliable and punctual partner.

02

Custom leather finishing

Every process comes from a direct discussion with the customer. Tirrena selects together with customers the products to be used, defining the most suitable weights and creating a tailor-made process that guarantees excellent results in terms of quality and performance.

03

Italian craftsmanship

Tirrena makes many finishing items within 48h/72h of receiving the order. Spray finishing makes it possible to meet the’requirement of scheduling, achieving the’goal of each tanning process.

Environmental Responsibility

By choosing water-friendly chemicals, adopting a circular system for waste disposal, and producing electricity through its photovoltaic plants, Tirrena invests in the future. The daily commitment to the’environment is real, tangible and certified. The LGW Gold LWG level testifies to the dedication to a greener future.

For which sectors does Tirrena Pelli apply spray finishing?

Tirrena for the Leather Industry

Spray finishing with a foaming machine is a useful technique also for the leather goods industry, where aesthetics and quality are prerequisites. This method makes it possible to apply finishes evenly, giving the leather a fine, customizable appearance, ideal for bags, wallets, and high-end accessories. Thanks to the precision of the foaming system, is it is possible to achieve sophisticated textures, glossy effects with varnish, matte or semi-gloss, and increased resistance to everyday stresses.

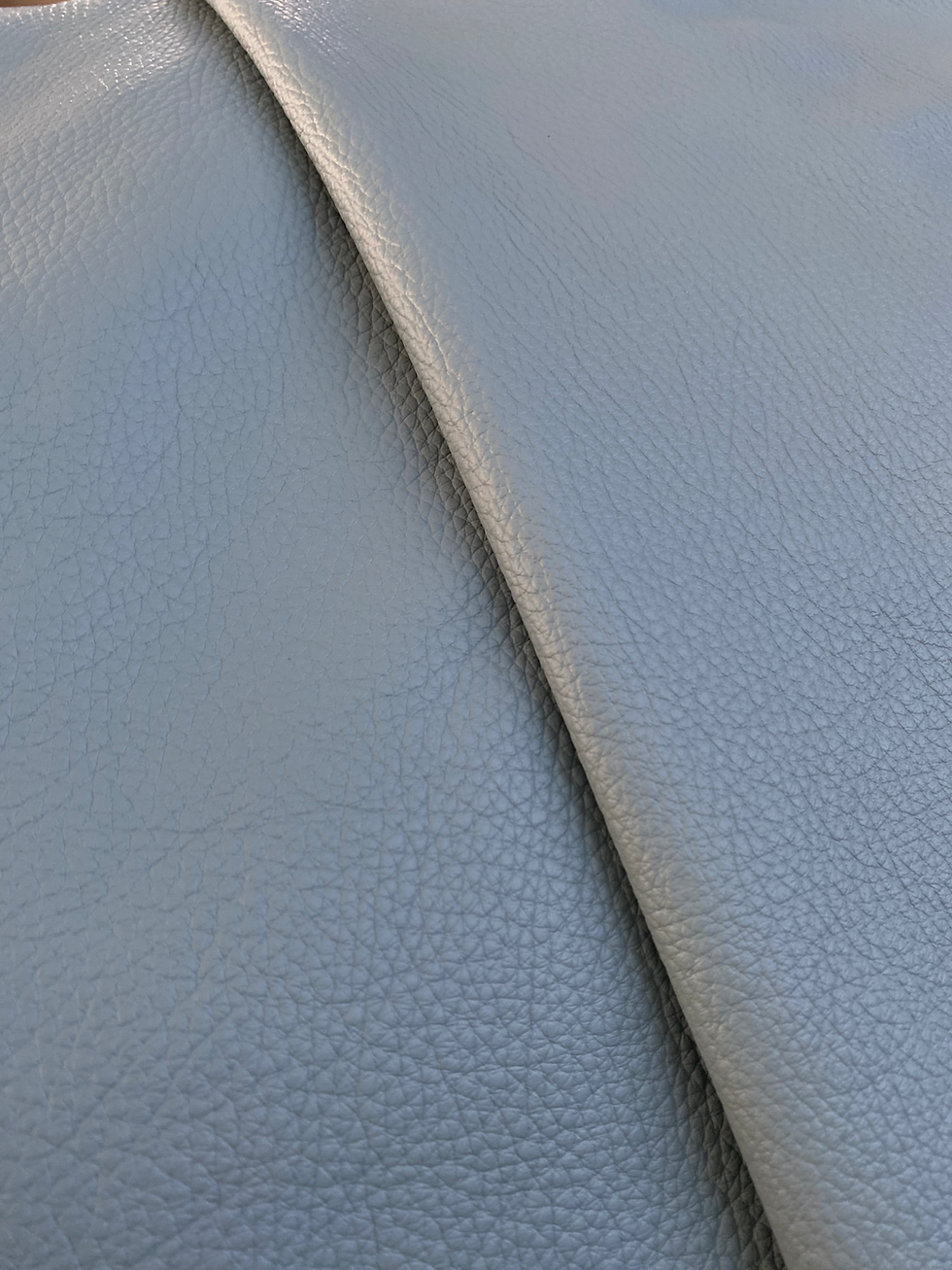

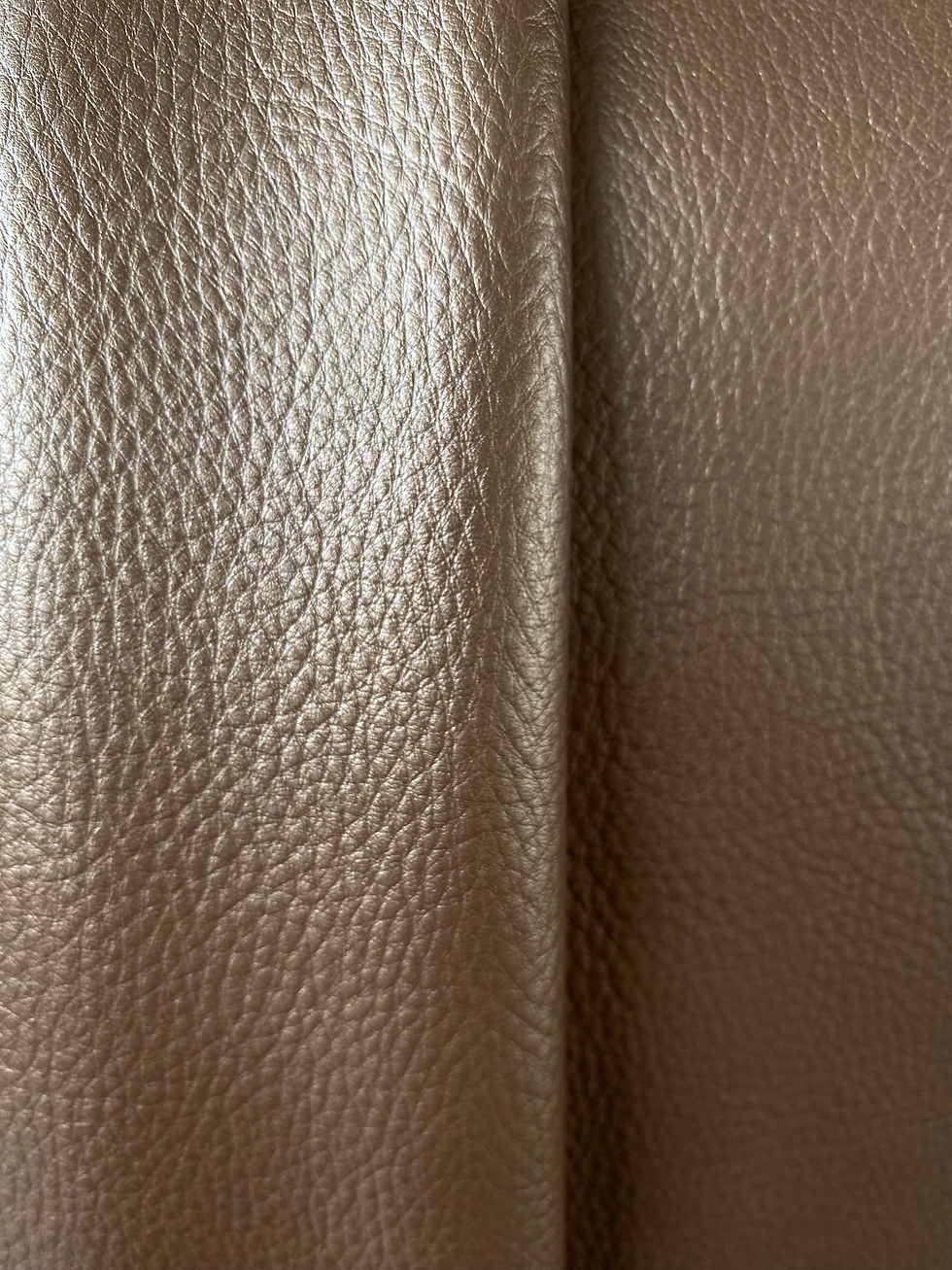

Leathers for furniture

Spray finishing gives leather an elegant, high-quality appearance, perfect for the needs of the upholstery industry. This technique allows for tailored aesthetic effects, such as matte, gloss or satin finishes, evenly distributing the color even on large or irregular surfaces.

In addition to aesthetics, refinishing ensures strength, durability, softness and naturalness of the leather, fundamental characteristics for upholstery and furniture accessories. For these reasons, spray and foamer finishing are particularly popular with high-end furniture designers and manufacturers.

Reverse Roller Refinishing for the Footwear Industry

Spray finishing with a foaming machine is an ideal technique for the treatment of leathers intended for the footwear industry, as it ensures a uniform, precise and highly customizable finish. This process uses specific guns to apply chemical compounds that create custom aesthetic effects, such as matte, glossy or textured finishes, enhancing the design of the footwear. In addition to the aesthetic result, this process improves the leather's resistance to wear and tear, making it suitable for daily, intensive use. Foam finishing thus represents an advanced solution for those seeking quality, durability and performance, meeting the needs of the most demanding footwear manufacturers.

Automotive and spray finishing

Spray finishing is a technology for the treatment of leathers intended for the automotive industry, where quality, resistance and uniformity are essential. Leathers finished with this technique offer high resistance to wear, UV rays and stains, while maintaining softness and flexibility. With spray finishing, it is possible to customize colors and effects, responding to the aesthetic and technical requests of manufacturers and designers, for interiors that combine elegance and durability.