/ WHAT WE DO

Refine in reverse

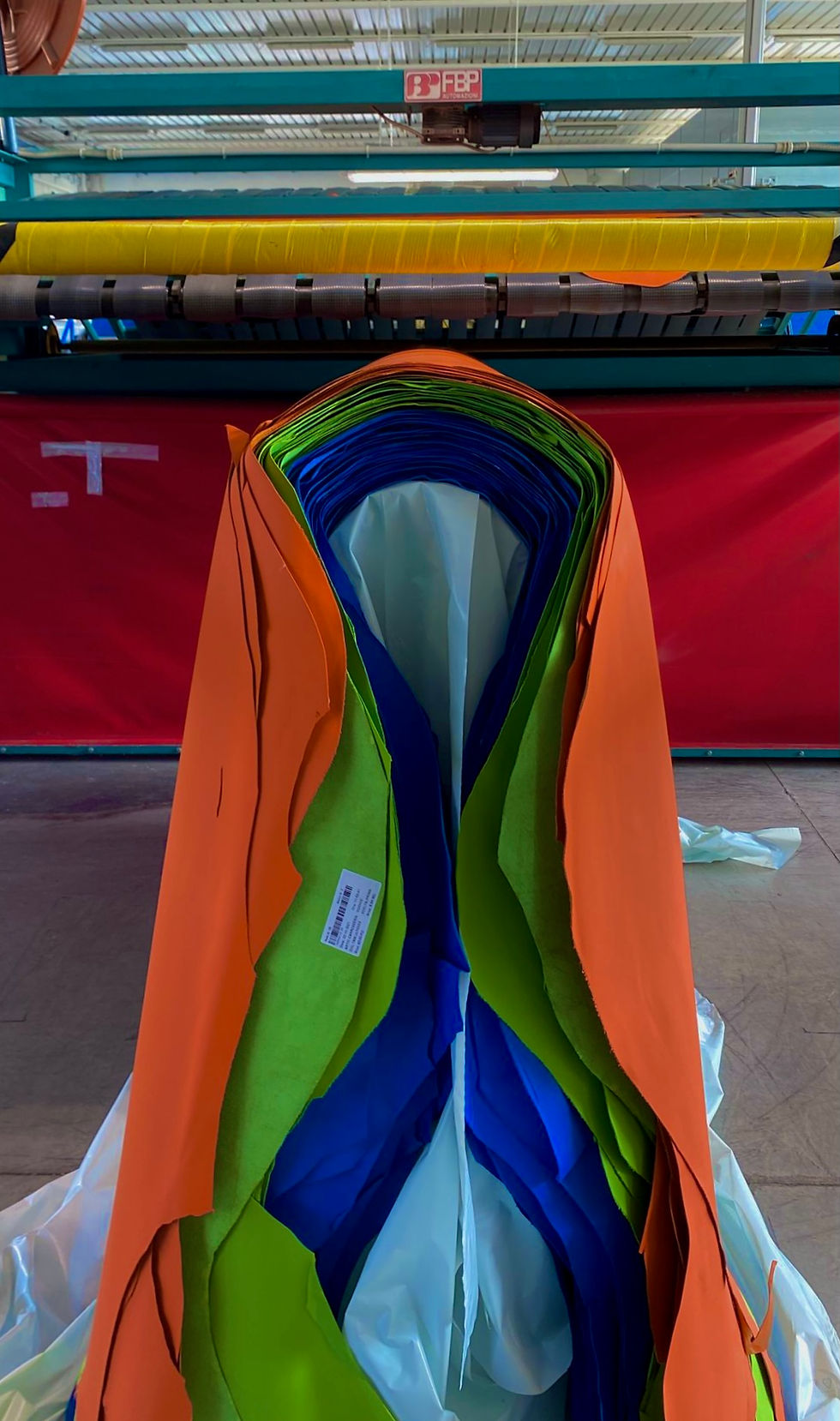

High degree of softness, spray-free finishing:TIRRENA LEATHER treats defective leathers, with major variations in thickness,with the reverse roller. Ideal on middles, whole skins, splits, buffed and full grain, reverse finishing is central in the production of items from buffed to full grain skins, matching splits, vintage items, waxed, oiled items for use in the furniture, automotive, footwear and leather goods industries.

What is reverse refining?

The revolutionary machine makes it possible to evenly distribute customer-selected treatment products, such as putties, pre-bottoms, oils and cold waxes, with weights ranging from 2.5 to 20 grams per square foot, over the entire surface of the leather through cylinders.

The sustainable choice: zero emissions and guaranteed savings

Zero emissions and savings on water consumption, product quantities, electricity and sludge disposal: reverse finishing is the convenient choice to have soft, high-quality leathers, including environmental ones. Tirrena Pelli invests in machinery to ensure processing that follows market trends but also the real need of customers. Cutting costs and bringing efficiency, with Tirrena Pelli is possible.

Do you want more information?

CONTACT US! FILL OUT THE FORM WITH YOUR REQUEST.

Why choose Tirrena Pelli?

To combine quality and respect for the’environment, Tirrena Pelli is the ideal choice. Each leather is processed with eco-friendly techniques that reduce environmental impact, ideal for those who want an authentic, nature-friendly product. Working with craftsmanship and technological innovation, Tirrena Pelli makes exclusive projects concrete.

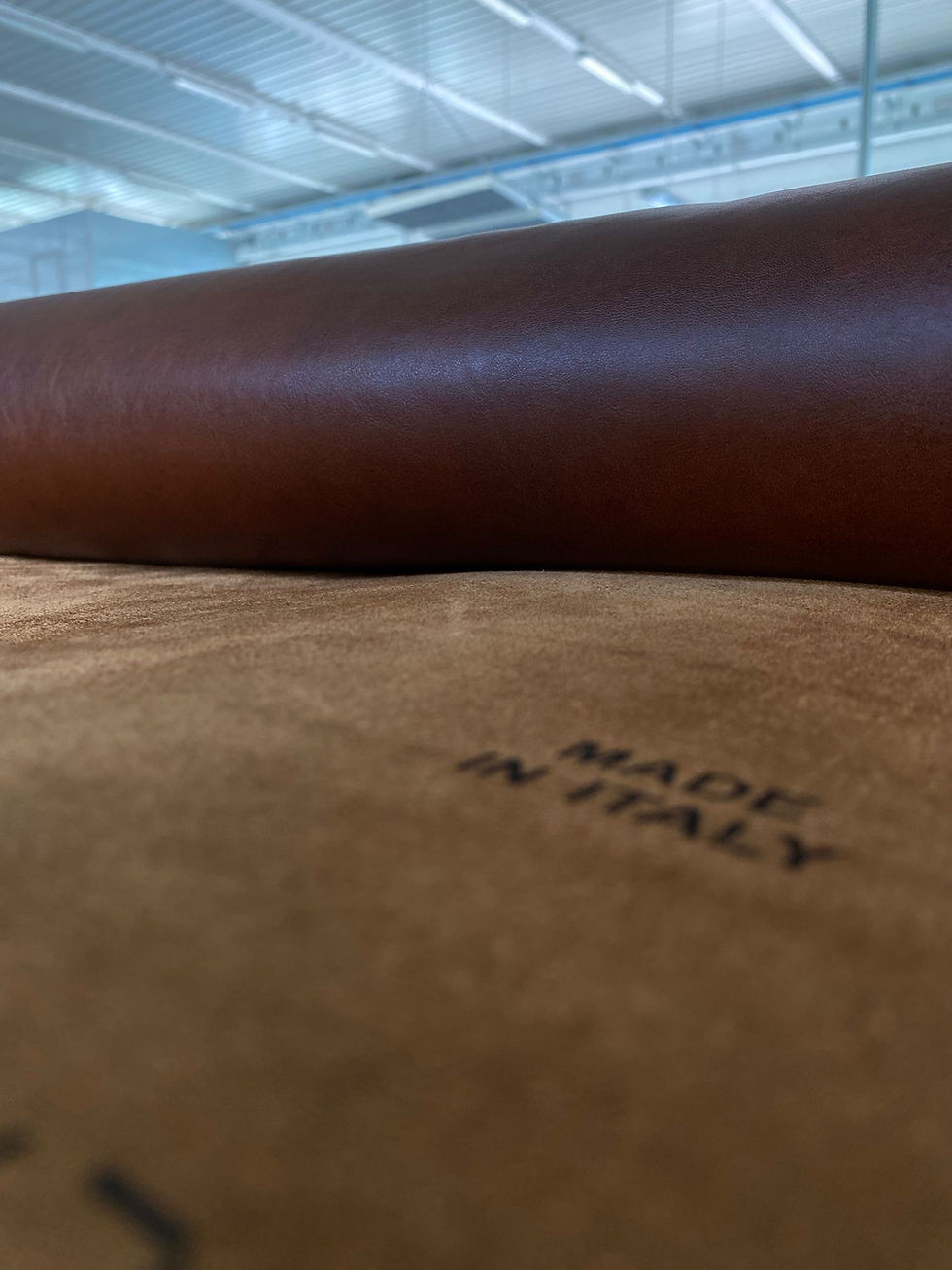

The certified traceability

The ethics and transparency, the certification that guarantees the transition from one phase to the next in the environmental perspective: Tirrena Pelli is LWG Gold certified and attested at the LGW Gold level. Processes are outlined with a green management that allows each customer to touch sustainability and keep track of every step.

The phases of the reverse finishing

01

Delivery and goods pickup

Welcome in the foreground: from delivery to goods pickup, Tirrena surrounds the customer step by step, even providing transportation to facilitate companies that need the service.

02

Product selection and weights

The manufacturing strategy is the result of ongoing dialogue. Tirrena Pelli works with the client to evaluate both the products to use and the specific weights, identifying the ideal process to ensure the desired result.

03

Leather finishing

Tirrena Leather Processing manufactures each item within 24/48h of receiving the order. Reverse finishing allows the programming on time, guaranteeing the efficiency essential to each project. The machinery operated by three operators, who follow the entire processing, is created to give homogeneous results and specific treatments, which are essential to then continue with the tanning process.

Sustainability

The choice of chemicals to water, the circular cycle of waste disposal and the production of electricity with photovoltaics are evidence of how much Tirrena Lavorazione Pelli invests for the future: a behavior that is also certified with the LGW Gold level of LWG. Discover the company’s green heart.

For which sectors does Tirrena Pelli apply reverse finishing?

Tirrena for the Leather Industry

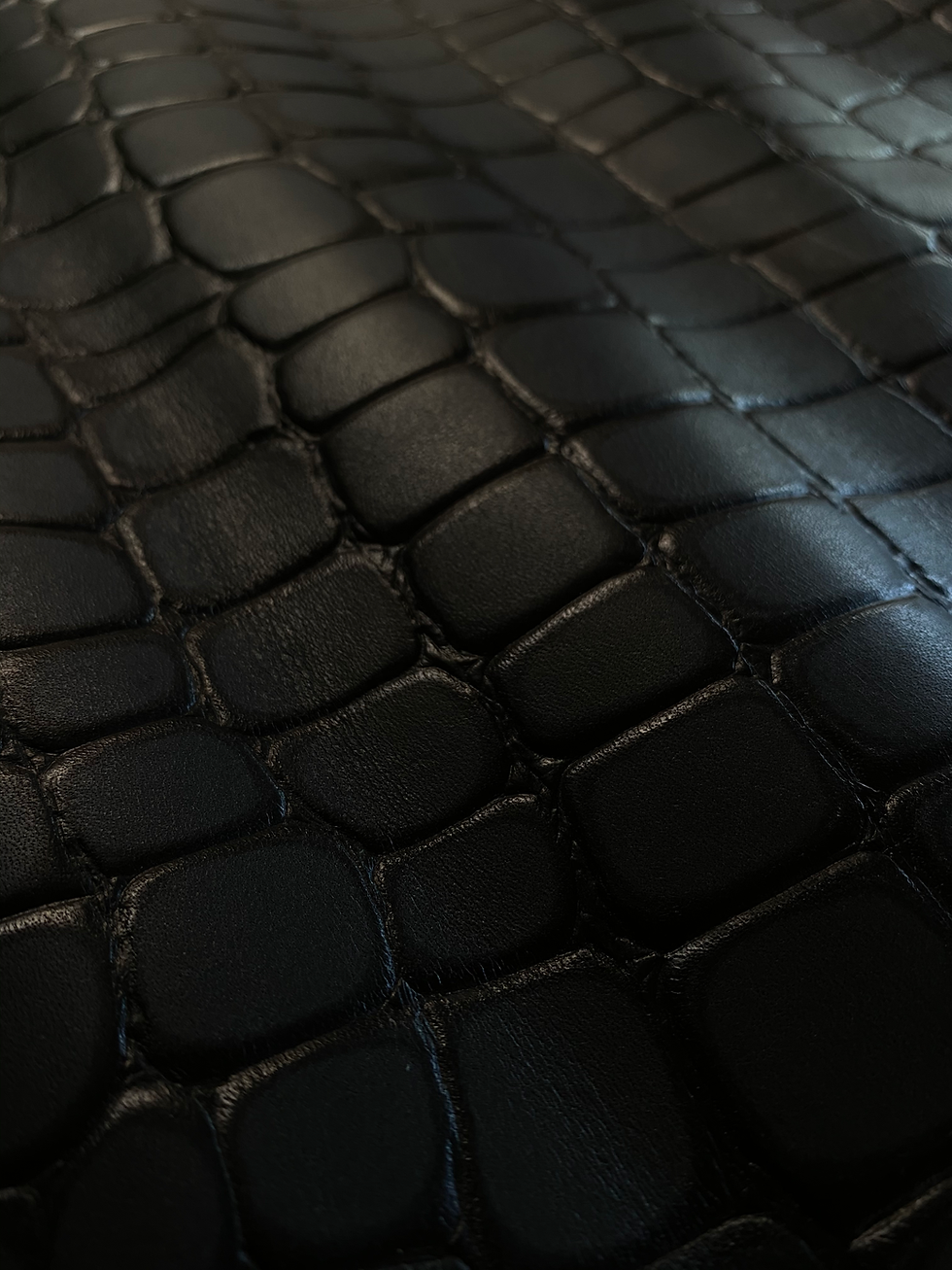

Reverse roller finishing is a fundamental technique for the leather goods sector, where aesthetics and quality; are prerequisites. This method makes it possible to apply finishes evenly, giving leather a fine, customizable appearance, ideal for bags, wallets, and high-end accessories. Thanks to the precision of the roller system, is it is possible to achieve sophisticated textures, glossy effects with varnish, matte or semi-gloss, and a resistance to daily stresses. Reverse roller finishing allows the natural beauty of the leather to be enhanced, ensuring a perfect combination of elegance and functionality, for products that stand out in the quality leather goods market.

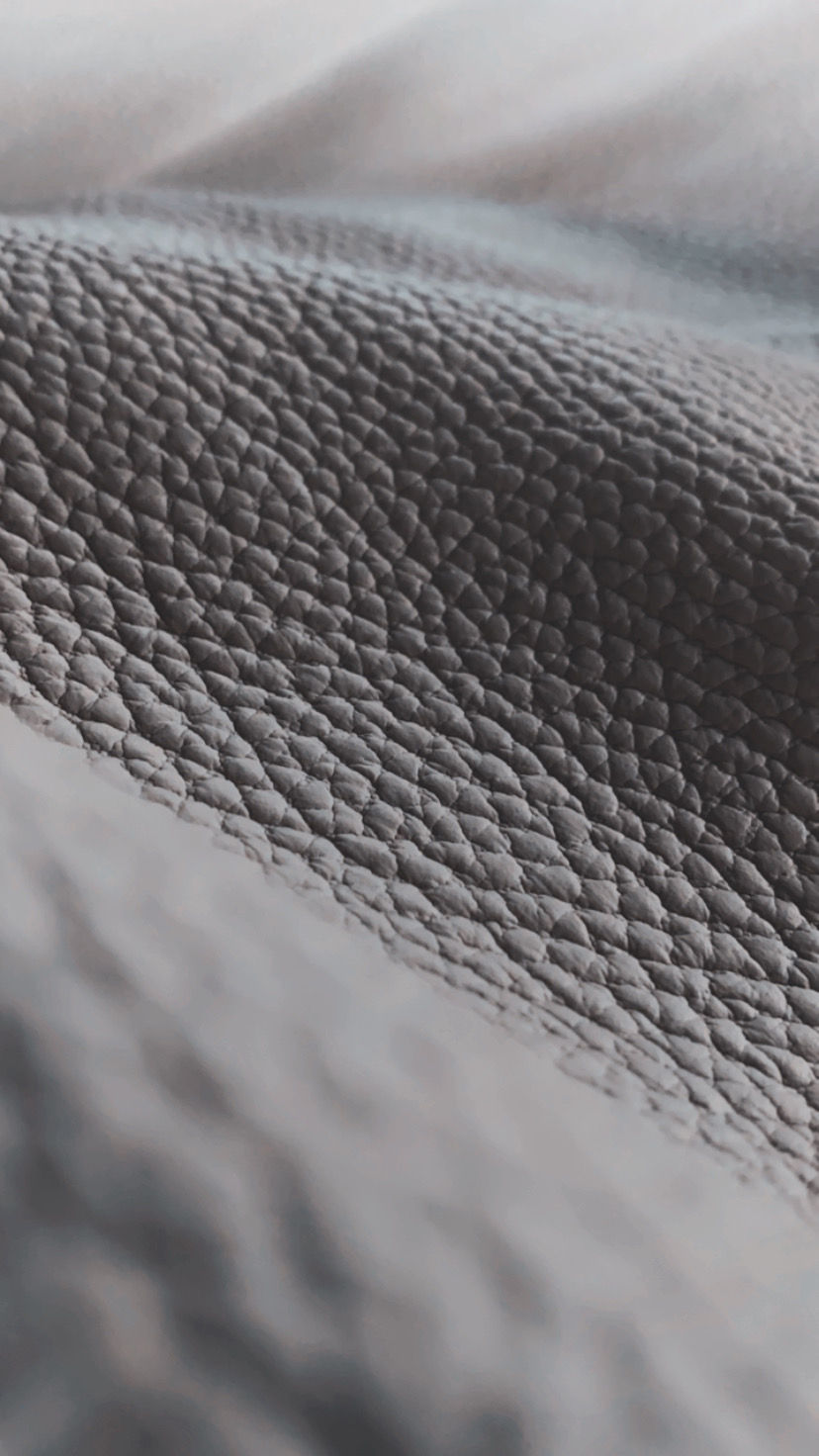

Leathers for furniture

Reverse roller finishing gives leathers a flawless appearance and uniform finish: ideal results for the upholstery industry. By distributing color and finish evenly, even on large and uneven surfaces, the process allows for high-quality effects such as matte, gloss or satin finishes. Strength, durability, softness and naturalness of the leather are guaranteed: results that make reverse roller finishing particularly appreciated by designers and manufacturers.

Reverse Roller Refinishing for the Footwear Industry

Reverse finishing is an ideal solution for treating leathers destined for the footwear industry, ensuring a precise, uniform and highly customizable finish. This process uses rollers to apply specific chemicals, allowing for flawless aesthetic effects such as matte, glossy or textured finishes that enhance the design of the shoe. In addition to the aesthetic aspect, this technique improves the leather's resistance to wear, making it suitable for everyday use. Perfect for meeting the quality and performance requirements demanded by footwear manufacturers, reverse roller finishing combines aesthetics, functionality and durability, ensuring a high-level result.

L’Automotive and reverse finishing

Reverse roller finishing is a technology for the treatment of leathers intended for the automotive industry, where quality, strength and uniformity are fundamental. Leathers finished with this technique offer high resistance to wear, UV rays and stains, while maintaining softness and flexibility. With reverse roller finishing, is it is possible to customize colors and effects, meeting the aesthetic and technical demands of manufacturers and designers, for interiors that combine elegance and durability.